About Alumverde and Its Panel Solutions

1.Overview of the Alumverde Brand

ALumverde is an innovative building material that harmoniously mates aluminum substrates with a layer of Surlyn resin co-extrusion. It was the culmination of a few decades of efforts on the part of the aluminum industry to marry the structural benefits of a metal with the warmth and texture of a natural wood. That innovation produced ALumverde™-a material that harmoniously combines the strength of aluminum with the beauty of wood, innovating beyond the outdoor building possibilities.

2.Core Features of Alumverde Panels

Alumverde panels are made from 6063-T5 aluminum alloy and co-extruded with Surlyn®, the same top-performing ionomer found in golf ball covers. The proprietary process achieves the ideal synergy of wood aesthetic appeal and the structural strength of aluminum. The co-extrusion coating not only provides UV resistance and water-resistance but also a realistically striking wood texture with the help of advanced 3D embossing techniques.

The primary models are AC WP18 (24mm thickness) and AC WP19 (21mm thickness), both with working widths of about 150mm and lengths 2.9m or 5.8m. Colors that are available are Teak, Oak, Dark Grey, Walnut, Antique, Ashwood, and IPE, but custom colors can be supplied on request.

Why Developers Trust Alumverde Panels

1.Long Lifespan

One of the major reasons developers use Alumverde panels is that they are highly durable. Our aluminum-wood composite items have the following quality control procedures in place: ISO Quality Management System, rate control of production, product standards, and stabilization processes after production. Every panel is strictly tested by a third party for UV resistance (3000-hour rated), mechanical (tensile strength: 207N/mm²), and fire performance (ASTM E84 Class A).

Aluminum’s oxide layer protects itself without affecting structure, even when there is internal oxidation. This inherent protection system radically eliminates corrosion threats, and the structural integrity is maintained for the long term.

Also, using Meyxteh’s unique method, our wall cladding is able to stop the heat by 30% compared to other product. This thermal regulation enhances life by reducing thermal expansion and contraction cycles.

2.High ROI

We offer premium return on investment (ROI) in the shape of minimal lifecycle costs. Its super low water absorption and expansion make it the most stable material for high-rise building. Such dimensional stability means less replacement and renovation in the long term.

Shipping and logistics also enhance ROI. Compared to wood-plastic composites, we benefit from 30% less ocean freight cost and 50% less risk of shipping damage. Moreover, anti-dumping duty exemption by HS code 76169990 (EU) makes us a cost-effective solution for global scale projects.

Installation cost saving is also prominent. Half weight than WPC cladding, it can be applied on double wider structure span and save significant labors and installation cost. Lighter weight is simpler to install and less labor-consuming, thus suitable for commercial developments.

3.Smaller Maintenance Calls

As compared to aged wood or WPC products that usually warp, fade, or mold, our panels last with less maintenance. To make use of ‘Surlyn’—the same product as golf surface as co-extrusion layer—it gives a much better protection than any coating against color fade and rust.

The panels are semie or fully encapsulated by type (for example, flooring versus cladding), preventing front-side corrosion. Even in wet conditions, the waterproof co-extrusion coating ensures maximum performance with minimum expansion.

This leads to reduced complaints and service calls from building owners—a major factor for real estate developers who value long-term satisfaction.

Practical Benefits in Real-World Applications

1.Flexibility Across Project Types

Our panels support a wide range of applications:

•Architectural Cladding: Used in high-end residential and commercial building facades where performance and aesthetics are of prime concern.

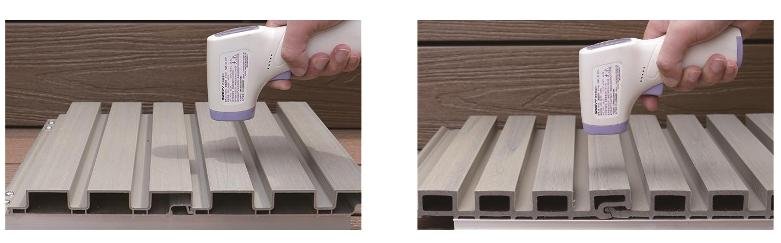

•Outdoor Decking: With materials like AD03 and LuxeFlow Decking™, used for balconies and terraces.

•Landscape Elements: Ideal for pergolas, louvers, sunshades, and handrails with products like square tubes (AC-ST01 to AC-ST05).

Aluminum can be as long as 6 meters without a risk of bending and cracking. This provides design freedom in horizontal as well as vertical directions.

With concealed fasteners such as U-brackets or riveted screws, installations are aesthetically neat yet structurally stable.

2.Green Building Compatibility

We are green building compatible in that it uses recycled material. Uses first-recycled Surlyn® resin and recycle-friendly aluminum materials. Not only is this in compliance with the circular economy principle, but it also assists with LEED credits and other green certifications.

Part of the product compliance and certifications also includes ASTM E84 Class A fire resistance and periodic EN 13501 testing for European economies. Such certification ensures public building suitability based on strict safety codes.

Even in extreme climates or city conditions susceptible to contaminants and moisture fluctuations, our two-layered technology—aluminum core and Surlyn shell—ensures enduring resilience without protective coatings or sealants needed.

Final Thoughts on Choosing Alumverde Panels

For architects in search of a premium-grade aluminum panel product that blends the optimum of metal strength and wood-like natural appearance, we stand out as the best option. The range—ranging from AC WP cladding series to LuxeFlow Decking™ to tubular structures—offers unmatched performance in fire resistance, heat insulation, UV protection, and mechanical stability.

Supported by a trust-worthy supply chain network, anti-dumping solutions for global trade, and professional-grade testing procedures, we provide peace of mind from procurement to installation. Whether constructing high-rise commercial skyscrapers or private residential villas, our co-extruded aluminum panels provide a convincing combination of design freedom, environmental sensitivity, and engineering excellence.

FAQ

Q: How long do Alumverde panels generally last outdoors?

A: Our panels are made of 6063-T5 aluminum alloy with a Surlyn co-extrusion layer added to it, which offers UV resistance, water resistance, and anti-corrosion. These are put through performance testing like 3000-hour UV tests (Grey Scale Rate 4.5) and ASTM E84 Class A fire rating for resistance, ensuring more than 25 years of lifespan in regular outdoor exposure. The quality assurance processes for our aluminum-wood composite products are:

ISO Quality Management Systemto minimize defects.

Q: What makes ALumverde panels distinctive from typical aluminum panels?

A: Rather than the cold industrial touch of typical aluminum, our panels employ a co-extruded Surlyn® layer to create a real wood-sensing surface without losing aluminum’s rigidity. In contrast to typical dull and uninspiring aluminum cladding, we put the same co-extrusion layer of new-generation WPC onto the aluminum.

Q: How do Alumverde products handle thermal expansion problems compared to other materials?

A: We only have a thermal expansion value of 25μm/m·℃ since it’s produced from an aluminum core structure. That is significantly lower than standard WPC products, enabling tighter joints without the risk of warping and cracking—even with prolonged sun exposure. Low expansion to provide smooth design without worrying about bending & cracking.

Q: What are the different installation methods for different Alumverde products?

A: Cladding panels feature concealed keel channels with U-clips; decking systems like AD03 use butterfly clips; tubes offer embedded U-bracket or threaded rivet provision. All systems offer clean finishes with high mechanical anchoring. Preparation: Pre-drill to the joistFix with screwJoin the tube to the joist