Discover how ALumverde combines aluminum strength with wood aesthetics through advanced co-extrusion technology for durable, fire-resistant outdoor solutions.

What Materials Are Needed to Produce ALumverde?

At the core of ALumverde’s exceptional performance are its carefully chosen materials, designed to offer a unique blend of strength and beauty.

Types of Aluminum Used in Production

The foundational element of all ALumverde products is 6063-T5 aluminum. This specific aluminum alloy is a standardized material known for its inherent strength and stability, which guarantees a remarkable durability exceeding 25 years. The use of aluminum as the core material ensures a higher standard of fire resistance crucial for many commercial and public buildings.

Coating and Extrusion Materials

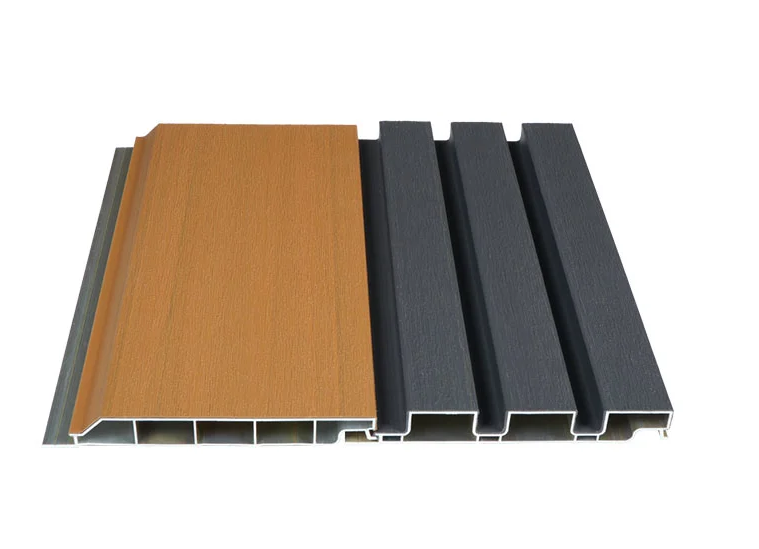

Complementing the aluminum core is a specialized outer layer: Surlyn resin. This material is notably known as the main material used in golf surfaces, indicating its excellent hardness and wear resistance. The Surlyn co-extruded layer typically has a thickness of 1mm. The aluminum core and Surlyn resin layer are stably bonded together using an eco-friendly composite resin adhesive as an inter-layer. This adhesive is highlighted as harmless and formaldehyde-free.

Tools and Machinery Required

For achieving multi-sided textures, four rollers can be simultaneously utilized. The entire operation indicates the need for sophisticated equipment to handle material feeding, pre-heating, cooling, and precise cutting.

How Does the Co-Extrusion Process Work?

The co-extrusion technique is central to ALumverde’s ability to combine the resilience of aluminum with the aesthetic of natural wood. This process is meticulously controlled to ensure optimal bonding and finish.

Step-by-Step Overview of the Co-Extrusion Technique

The production of ALumverde materials follows a detailed multi-stage process:

- Material Preparation and Feeding: The journey begins with the preparation of raw materials. Aluminum profiles are then fed online and transported to the co-extrusion machinery. Simultaneously, the Surlyn resin is fed into the co-extrusion equipment.

- Extrusion and Cooling: A critical step involves pre-heating the aluminum to ensure its temperature is close to that of the melted adhesive glue, which enhances adhesion. Following this, the glue and Surlyn are co-extruded onto the aluminum profile, effectively coating it. Depending on the product’s design, a texture grain can be applied during this phase; however, not all finishes, such as brush or sand, require texturing. For products like tubes, texturing can be applied to all four sides simultaneously using multiple rollers. After the co-extrusion, a water cooling stage is crucial for the rapid formation and setting of the coating layer. This step also prevents debris from blending into the surface before it solidifies.

- Surface Treatment and Finishing: Once cooled, the products undergo a stacking phase to further facilitate their formation and stabilization. Initially, the Surlyn coating has a ‘plastic’ feel. To achieve the desired authentic wood-like feeling, a surface treatment, specifically sanding, is performed. This sanding process requires a delicate balance: if too light, the wood feeling is not prominent; if too heavy, the surface can become furry and impact the appearance. Notably, some special textures, such as Woodweave, may look better without this sanding treatment. Finally, the products are meticulously prepared for delivery, including wind-blowing away aluminum particles from internal spaces and surfaces to ensure cleanliness and prevent scratches, before being packed in shrinkage film and placed on pallets. The final step is loading the finished products for shipment.

Benefits of Co-Extrusion in Aluminum Production

The co-extrusion technique offers numerous advantages for ALumverde products:

- Authentic Aesthetic: It delivers an authentic wood feeling and appearance with a multi-layered, 3D wood grain texture that includes dynamic shadows, tactile ridges, and multi-tonal hues, mimicking real timber.

- Enhanced Performance: Products boast better heat resistance, reducing heat absorption by up to 30% through Mexytech’s special technique, offering a more comfortable experience under the sun.

- Superior Fire Safety: An excellent fireproof rate is achieved, meeting aluminum standards of fire resistance and exceeding ASTM E84 Class A standards.

- Exceptional Durability: The co-extrusion results in better stability and longer durability, with low expansion that allows for seamless designs without concerns of bending or cracking. The Surlyn layer provides ultra-shield protection against UV rays, water absorption, and extreme weather, ensuring decades of fade-free beauty.

- Ease of Installation: The light weight of ALumverde products, often half the weight of similar wood-plastic composite (WPC) products, can save 1/3 of time and labor during installation and potentially cut labor costs by 40%. The excellent strength allows for lengths up to 6 meters.

- Design Flexibility: The co-extrusion process enables a bi-color option, providing two colors in one piece for double opportunities in sales and design.

Why Is Quality Control Essential in Producing ALumverde?

Quality control is paramount in the production of ALumverde, ensuring that each product meets stringent performance and aesthetic standards.

Inspection Procedures at Each Stage

While the sources do not explicitly detail specific inspection procedures at every stage, the meticulous description of the manufacturing process – including precise pre-heating for better adhesion, careful water cooling to prevent impurities, and balanced surface treatment for optimal appearance – inherently suggests a strong emphasis on quality at each step. The blowing away of aluminum particles before packaging also indicates attention to detail for a clean final product.

Testing for Durability, Strength, and Appearance

ALumverde products undergo rigorous testing to validate their performance characteristics. Key tests and results include:

- UV Resistance: Tested under ASTM G154-23 Cycle1 & ISO 105-A02:1993/Cor.2:2005, achieving a Grey Scale Rate of 4.5 in 3000 hours, demonstrating its long-lasting color fastness.

- Fire Resistance: Products are tested to ASTM E84 Class A and are undergoing testing for En 13501, affirming their high fireproof rate.

- Mechanical Strength: Tested for Tensile Strength at 207N/mm² and Non-proportional Elongation Strength at 175N/mm².

- Hardness: Products exhibit a Hardness rating of 9-10.

- Durability: The 6063-T5 aluminum core is standardized for strength and stability, ensuring durability over 25 years.

Certifications and Industry Standards Followed

ALumverde adheres to recognized industry standards to certify its product quality. This includes using 6063-T5 aluminum which meets universal standards, and compliance with ASTM E84 Class A for fire safety. Ongoing testing for En 13501 further underscores their commitment to high standards, particularly for the European market.

How Can Sustainability Be Achieved in ALumverde Production?

ALumverde is deeply committed to eco-conscious design and environmental responsibility.

Use of Recyclable Materials

A significant aspect of ALumverde’s sustainability is its material composition: the products are built with 80% recycled aluminum and fully recyclable materials. This commitment reduces environmental impact without compromising performance. The company’s vision is to offer an aluminum-based, wood-free material that replicates nature’s beauty without depleting natural timber.

Energy-Efficient Manufacturing Practices and Waste Reduction Strategies

While the sources emphasize the use of recycled content and the eco-friendly nature of their composite resin adhesive (zero-formaldehyde), they do not provide specific details on energy-efficient manufacturing practices or explicit waste reduction strategies beyond the inherent recyclability of the materials themselves. The overall “green” concept and “nature care” vision suggest a broader commitment to sustainable production.

Where Are ALumverde Products Commonly Used?

ALumverde products are highly versatile and are specified for a wide range of applications, particularly where strict standards for fireproof performance and stability are required.

- Decking: Ideal for high-rise balcony decking and outdoor flooring solutions, offering non-combustible and low-maintenance properties. The LuxeFlow Decking specifically features innovative built-in drainage channels for efficient water management.

- Cladding/Soffit: Perfect for high-rise buildings, modern architectural designs, facades, and soffits, providing a realistic 3D wood feeling with superior UV protection and fire resistance.

- Tube Series: Offers limitless design possibilities for various creative projects, including fences, pergolas, railings, and decorative screens.

- General Applications: Suitable for commercial facilities, public premises, and general outdoor structures that demand high performance and aesthetic appeal.

What Sets ALumverde Apart from Other Aluminum Suppliers?

ALumverde differentiates itself through its innovative technology, customer-centric approach, and commitment to high standards.

Innovation in Design and Engineering

ALumverde is recognized for its “next generation” aluminum products.

- Co-Extrusion Excellence: The use of Surlyn co-extrusion creates an authentic 3D wood grain texture that transforms metal into a warm, tactile design. This is a “reinforced patent design”.

- Advanced Features: The “LuxeFlow Decking” features an innovative design with in-built drainage channels to ensure efficient water gathering and drainage.

- Heat Reduction: A special blending and molding technology results in 30% less heat absorption in outdoor use compared to other aluminum products, enhancing comfort.

- Bi-Color Option: The decking offers a bi-color option, providing two colors in one piece for enhanced design flexibility.

Customer-Centric Service Model

ALumverde is dedicated to meeting customer needs and supporting diverse projects:

- Customization: They offer a six-color spectrum (Walnut, Antique, Dark Grey, Teak, IPE, Ashwood) with three major texture grains (Wood Grain, Brush, Woodweave), and support many more custom options for colors and textures. Customized profiles are also supported for full container load (FCL) orders.

- Support Services: ALumverde provides engineering assistance and offers free samples for prospective customers to experience the product firsthand. They also welcome inquiries from potential distributors.

- Effortless Installation: With a focus on user experience, ALumverde products are designed for easy and cost-effective installation, saving time and labor. Pre-engineered accessories like hidden clips and custom trims ensure flawless alignment.

Competitive Pricing with Premium Quality

ALumverde positions itself as a provider of “higher end, better decking”. By offering superior performance characteristics such as fire resistance, durability, and a realistic wood aesthetic, coupled with cost-saving benefits like reduced installation time and labor due to lighter weight, ALumverde provides a premium quality solution that offers competitive value. Furthermore, ALumverde wall cladding benefits from an anti-dumping exemption.

Conclusion

ALumverde represents a significant leap forward in outdoor construction materials, offering an innovative blend of aluminum strength and natural wood aesthetics. Through its sophisticated co-extrusion technology, use of high-performance materials like 6063-T5 aluminum and Surlyn resin, and stringent quality control, ALumverde delivers products that are exceptionally durable, fire-resistant, and aesthetically pleasing. Coupled with a strong commitment to sustainability through recycled materials and a customer-centric service model that supports customization and ease of installation, ALumverde is truly setting a new standard for modern architectural solutions in decking, cladding, and tube applications. This “next generation” material is poised to transform projects into “enduring masterpieces” that are both beautiful and environmentally responsible.

FAQs About Producing ALumverde

1. What is co-extrusion in aluminum production?

In ALumverde production, co-extrusion is a specialized manufacturing technique where a 6063-T5 aluminum alloy core is stably bonded with a Surlyn resin outer layer, using an eco-friendly composite resin adhesive as an inter-layer. This process creates a hybrid material that combines the high strength and stability of aluminum with the authentic appearance and tactile feel of natural wood, offering superior performance in terms of durability, fire resistance, and aesthetics.

2. Are ALumverde products environmentally friendly?

Yes, ALumverde products are designed with an eco-conscious approach. They are made with 80% recycled aluminum and are fully recyclable themselves, significantly reducing their environmental footprint. The company’s vision is to provide a wood-free, aluminum-based alternative that mimics nature’s beauty without contributing to the depletion of natural timber. Additionally, the composite resin adhesive used in production is harmless and formaldehyde-free.

3. Can customers request custom aluminum profiles from ALumverde?

Yes, ALumverde offers extensive customization options for its products. Customers can request customized profiles, textures, and colors beyond the standard offerings. While customized profiles are generally supported for Full Container Load (FCL) orders, the Minimum Order Quantity (MOQ) for customized colors is negotiable, indicating flexibility to meet specific project needs. ALumverde also provides engineering assistance to help realize unique design visions.