Head down any street in a quake zone or along a windy shoreline and you’ll spot regular panels pulling away after just a couple of rough years. They swell when the thermometer climbs past 40 °C, shrink again when it drops below zero, the clips loosen, and pretty soon the whole wall rattles like a tin shed in a gale. ALumverde ran into that exact headache on job sites years ago. Our fix was simple: hang on to the brute strength and low weight that only aluminum gives you, then wrap it in a skin that looks and feels like real wood. The end result is a wall that refuses to budge no matter how hard the building rocks.

The Challenge: Building Resilience in Extreme Environments

These days almost every big job wants cladding that’s built around aluminum. It has to take a beating and still deliver that warm timber look owners keep asking for. High-rises demand almost no movement when the temperature swings, good fire behavior, and as little dead weight as possible. Wood-plastic boards usually flex too much and burn too easy. And plain aluminum composite sheets just look cheap and cold. ALumverde cracked both problems with one product—an aluminum-resin mix that gives deep color and grain while still passing the toughest high-rise rules.

ALumverde: A Simple Introduction

ALumverde builds aluminum co-extrusion cladding, decking, and tube systems. We comes from more than twenty years of messing around with composites on real projects.

ALumverde Technology: A Hybrid Approach to Stability

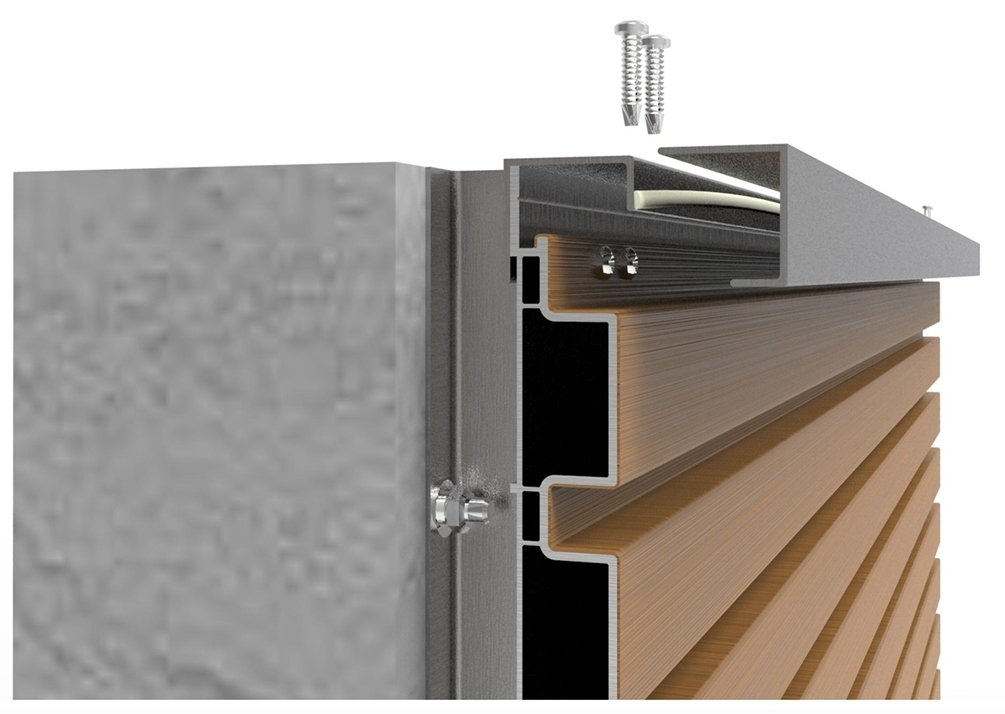

The reason ALumverde aluminum co-extrusion cladding stays put when everything else is shaking comes down to how the layers go together and the way the factory runs the line. Put it side by side with older stuff and the difference jumps out.

The Strength of the Aluminum Core

Every plank and every tube—from the AC-ST01 through AC-ST06 range to the Slat and Shiplap profiles—starts life as solid aluminum that won’t burn. That metal heart gives the wall the backbone it needs without piling on extra tons. On a fifty- or sixty-story job that weight saving really matters.

Co-Extrusion: Surlyn Armor for Durability

A thick Surlyn resin skin gets melted right onto the aluminum while both are still hot, so the two parts lock together for good. That outer shell laughs at water, shrugs off sun fade, and throws in another layer of fire protection. It also carries a proper 3-D wood grain you can feel with your fingers. Colors stay sharp for years because the resin blocks UV like a brick wall.

Engineered for Movement: Stability in Seismic and High-Wind Regions

In towns that sit on fault lines or coasts that catch cyclones, the big fear is panels shifting and ripping their clips clean off. ALumverde attacks that worry with a couple of smart tricks.

Double-Structure Design for Enhanced Strength

Instead of one thin skin, ALumverde runs two layers that lock together. That setup spreads wind and quake loads so the wall doesn’t twist the way single-sheet stuff does. Wind-tunnel reports on the Shiplap cladding show almost zero movement even when gusts hit ridiculous speeds. The double layout is the main thing that keeps it calm.

Zero Expansion and Ultra-Stable Performance

Most outdoor boards grow a little in summer and pull back in winter. On a thirty-meter stretch that tiny shift is enough to work screws loose over time. ALumverde aluminum co-extrusion cladding barely budges—less than coffee-stirrer thickness from minus twenty to plus eighty degrees. Because it stays put, the clips never slack off. Pair it with the matching aluminum joists and all the proper corner and end trims, and the whole wall acts like one solid piece from ground to roof.

Beyond Stability: Aesthetics and Safety Redefined

A wall that just hangs on isn’t enough. It has to look right and keep everyone safe when things go wrong.

The Natural Aesthetic and 3D Wood Grain

Stand in front of an ALumverde wall and you’d swear it’s solid teak or old walnut. Favorite colors run Teak, Antique Walnut, Walnut, Ashwood, IPE, and Dark Grey. You can order Woodweave, heavy Wood Grain, or a softer Matte Brush finish. Builders love finally getting real hardwood looks on a tower without the rot, bugs, or yearly oiling.

Class A Fire Safety Standards

Tall-building fire codes don’t mess around. The aluminum core won’t burn, period. The whole panel sails through ASTM E84 and pulls a clean Class A—the top mark you can get.

Conclusion

In cities that rattle and coastlines that take a beating, ALumverde Aluminum Co-Extrusion Cladding just sits there quiet and steady. Fireproof aluminum inside, tough Surlyn outside, and that clever double-layer build let designers use warm timber looks on the tallest, roughest jobs without losing sleep. The wall stays calm while the building does its dance with wind and ground—a dead-simple mix of good looks, real safety, and honest toughness that works.

FAQ

Q: How does ALumverde Aluminum Co-Extrusion Cladding achieve stability in high-wind regions?

A: The double-structure spreads the load, and the zero-expansion aluminum core keeps every clip tight no matter what.

Q: Is ALumverde Aluminum Co-Extrusion Cladding an Aluminum Composite Panel (ACP)?

A: No. It’s solid aluminum with a co-extruded Surlyn skin—totally different material from regular ACP/ACM or WPC.

Q: What fire rating does ALumverde Aluminum Co-Extrusion Cladding hold?

A: Full Class A under ASTM E84, thanks to the fireproof core.

Q: Can ALumverde products be customized for specific architectural needs?

A: Yes. Plenty of sizes, colors, grains, and factory engineering help so every job gets exactly what it wants.