Understanding Co-Extrusion Aluminum Cladding

What Is Co-Extrusion Aluminum Cladding

Co-extrusion aluminum cladding is a innovative building cover that mixes a tough aluminum middle with a guard outside skin. This setup brings strong work and a pretty look. The way puts 6063-T5 aluminum alloy together with Surlyn co-extruded coat. It uses special glue cover tech. This owned step gets the right blend of wood-like sight and aluminum’s firm hold. You get many layers in the end. They give top sun block, color keep, and steady shape.

The outside Surlyn skin comes from golf ball tops. It brings hard wear and full weather guard, so this cover fits buildings in rough spots like the beach or wet areas.

Why ALumverde Uses Co-Extrusion Technology

WPC moved to its next round, called Capped WPC. This gave a big jump: a guard tech that fixed old weak spots. And it held the true wood cozy feel and touch. This innovative idea kicked off ALumverde—a product that joins aluminum power with wood charm without a hitch.

ALumverde picks up better mark fight, holds top color long, and keeps high fire safe. The tech lets us put on 3D wood line that stays bright and good to touch for years. This keeps the look even and real.

Benefits of Aluminum Cladding in Retrofits

Enhanced Fire Safety with ALumverde Aluminum Cladding

Fire safety is crucial in renovation projects. ALumverde aluminum cladding meets the ASTM E84 Class A standard, ensuring it does not ignite. This makes it ideal for replacing old wood or composite panels. With an aluminum core, it provides far stronger fire resistance than standard WPC or ACP sheets, fully meeting the higher fireproofing requirements of commercial and public buildings.

Improved Aesthetics with Wood-Looking Aluminum Panels

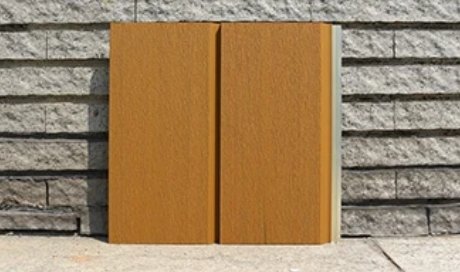

ALumverde’s co-extrusion aluminum cladding changes the aluminum sight. Different from traditional aluminum cladding, which is plain and monotonous, we use the same co-extrusion layer of the latest generation WPC on the aluminum. An extra layer brings a brand-new 3D-touching and beautiful wood feeling for building design. Normal ends are Walnut Brown, Teak Natural, Oak Light, and Dark Grey. We back full custom colors to fit any build plan.

Durability Against Weather and Corrosion

Normal wood or PVC covers do not hold up like ALumverde panels. The water block co-extrusion coat boosts work with little growth. The rust-resistant Surlyn top and closed sides stop acid rain, sun harm, and saltwater damage. This makes them good for beach jobs.

Applications in Wall Retrofit Projects

Ideal Scenarios for Replacing Old Wall Cladding

ALumverde co extrusion aluminum cladding fits best for old buildings with burn or rot stuff. Folks use it in jobs that need fire bumps or new front looks. Panels often go right over old builds, so this cuts down on framing trouble.

Versatility Across Building Types

ALumverde is light but hard. This helps stick it on many kinds—from home flats to schools and care spots. Aluminum can achieve a length up to 6 meters with no concern of bending or cracking. The part panel setup allows for bendy layout plans.

ALumverde Product Features Overview

Surface Finish Options and Texture Choices

ALumverde gives lots of top feels, like brush, wood line, and plain. Advanced wood grain, brushed metal, and 3D embossed patterns replicate the visual and tactile authenticity of natural timber.

Specific Product Models from ALumverde Lineup

- ALumverde Slat Cladding: This is built for up-down puts in thin wall spots. It has a hidden fix setup with a real wood feel. The slim shape lets fun design lines, but keeps building strength.

- ALumverde Shiplap Cladding: This fits wide wall spots. It has a better lock part for a smooth lineup. The big cover speeds put up and keep an even sight nice.

Installation & Sustainability Advantages

Quick Setup, Long-Term Savings

ALumverde panels weigh half as much as WPC cladding, cutting labor and structure costs. The hidden lock design allows direct mounting over old surfaces without exposed screws, speeding installation and reducing expenses.

Low Maintenance, Eco-Friendly Choice

No painting or sealing is needed—just simple washing keeps panels clean. Made from recyclable aluminum and Surlyn resin, ALumverde minimizes waste and supports LEED and green building goals while offering lasting durability and energy efficiency.

By mixing charm with tough build in new co-extrusion tech, ALumverde gives a solid pick for swapping old covers. It brings better safety rules and boosts the build look. For your fix plan or samples, contact us.

FAQ

Q: How does ALumverde aluminum cladding compare with traditional ACP panels in retrofits?

A: Unlike conventional ACP panels that may lack fire resistance and weather durability, ALumverde’s co-extrusion aluminum cladding is enhanced with a Surlyn layer, providing a Class A fire rating, UV protection, and waterproof resilience—making it the perfect choice for retrofits needing compliance with updated building codes.

Q: Can the ALumverde panels be customized to match my existing building palette?

A: Yes. ALumverde supports customized colors, textures, and finishes to match specific architectural requirements. Minimum order quantities apply depending on customization type.

Q: Are there any structural limitations when using ALumverde panels for tall buildings?

A: No. Aluminum can achieve a length up to 6 meters with no concern of bending or cracking. Its low water absorption rate ensures excellent dimensional stability even on high-rise facades.

Q: What makes ALumverde suitable for coastal retrofit applications?

A: The Surlyn co-extrusion layer provides superior resistance against salt spray, corrosion, and UV exposure. It prevents color fading and rust even under extreme weather conditions.