In the dynamic world of architectural design and building materials, innovation is key to meeting the evolving demands for aesthetics, durability, and safety. For decades, the industry has strived to blend the inherent strength and versatility of metal with the timeless warmth and inviting appeal of natural wood. While various solutions have emerged, many have fallen short in delivering a truly authentic tactile experience or overcoming critical limitations such as UV resistance and waterproofing, especially in harsh environments. This pursuit has led to the development of a groundbreaking material that redefines what’s possible in outdoor construction: ALumverde.

ALumverde is not just a product; it’s a comprehensive concept, a sophisticated technique, a versatile system, and a forward-thinking vision. It seamlessly marries the robust strength of aluminum with the authentic beauty of wood, offering an unparalleled alternative that addresses the shortcomings of traditional materials like natural wood, Wood-Plastic Composite (WPC), and even conventional powder-coated aluminum. This blog post will delve into what makes ALumverde a definitive choice, exploring its innovative technology, comparing its superior performance against other common building materials, and highlighting why it’s particularly ideal for demanding applications like high-rise buildings.

ALumverde’s Innovative Technology: The Foundation of Superiority

The true distinction of any advanced building material lies in its core technology. ALumverde’s revolutionary properties stem from a unique blend of materials and a meticulously engineered production process, setting a new benchmark for performance and aesthetics in the industry.

At the heart of ALumverde’s superior performance lies its innovative technology, which combines a robust aluminum core with a high-performance Surlyn resin co-extrusion layer. This hybrid composition and the precise manufacturing stages are what truly differentiate ALumverde from other building materials, enabling it to offer a unique set of advantages.

The Revolutionary Surlyn Resin Co-extrusion

ALumverde’s signature is its technique of combining a high-performance Surlyn resin with an aluminum core. Surlyn, a material renowned for its use in golf balls due to its superior performance in weathering resistance and durability, transforms the aluminum product in remarkable ways when applied as a composite material. This innovative fusion not only creates a lifelike wood texture but also unlocks a broader spectrum of colors and surface finishes. Furthermore, it elevates the material’s performance by delivering exceptional stability, durability, and resistance to environmental stress.

The Hybrid Composition

The foundation of ALumverde products is a 6063-T5 aluminum profile. This specific aluminum alloy is chosen for its standardization strength and stability, ensuring durability for over 25 years. The aluminum core is precisely extruded with the tightest tolerance in profile dimensions to ensure the stability needed for the seamless application of the resin layer.

Bonding this robust aluminum core to the outer Surlyn resin layer is an eco-friendly copolymer resin adhesive, which acts as an inter-layer. This adhesive is rigorously tested to meet the highest environmental standards, ensuring a durable, seamless fusion that enhances both performance and sustainability. The Surlyn resin is then co-extruded onto the aluminum surface under precise temperature and pressure, forming a 1mm co-extrusion outer layer. This outer layer is critical for its excellent hardness and wear resistance.

Key Stages of Production

The production of ALumverde involves several meticulously controlled stages:

- Aluminum Profile Extrusion and Online Transit: Precision is paramount, maintaining tight tolerances for the aluminum profiles to ensure stability for the resin application.

- Outer Layer Mixing: This stage is crucial for color artistry, where subtle adjustments in the base plastic and color masterbatch create natural variations and influence the resin’s flow and final surface flatness for a flawless finish.

- Glue Coating: An eco-friendly copolymer resin is applied, forming a critical bond between the aluminum and Surlyn resin. Pre-heating the aluminum to a temperature close to the melt glue enhances adhesion.

- Protection Layer Shielded (Co-extrusion and Texture Graining): Surlyn resin is extruded onto the surface under precise temperature and pressure to maintain color consistency and form the panel’s texture. A grain roller adds the final touch, creating a lifelike wood pattern. Not all products require texture graining; some, like brush or sand finishes, do not. Maximum four-sided texturing is possible, requiring four rollers simultaneously.

- Water Cooling: This is an important step for the fast-formation and stabilization of the coating layer, and it also prevents debris from blending into the surface before cooling.

- Stacking: Products are left to stack for further formation and stabilization.

- Surface Treatment and Fine Cutting: The final stage defines the product’s tactile and visual character. Deeper sanding delivers a textured, authentic wood feel, while lighter sanding creates a smoother surface. This process also influences color variation. Prior to surface treatment, the Surlyn coating might feel “plastic”; sanding is crucial to achieve the wood-like feel. A balance is needed in sanding – too light, no wood feeling; too heavy, surface becomes furry. Some textures, like Woodweave, look better without surface treatment. After treatment, aluminum particles are wind-blown away to ensure cleanliness and prevent scratches.

- Packaging and Loading: Profiles are packed in shrinkage film and then placed on pallets.

Comparing ALumverde to Traditional Building Materials

Understanding ALumverde’s true value comes into focus when directly comparing it with materials that have long dominated the construction industry. While each traditional material offers certain advantages, they also come with significant limitations that ALumverde is specifically engineered to overcome.

Here’s how ALumverde stacks up against its competitors, showcasing its superior attributes:

Against Natural Wood: Addressing Limitations in Durability and Maintenance

Natural wood, despite its inherent beauty, presents significant challenges in terms of durability, maintenance, and long-term stability, particularly in outdoor or high-rise applications.

| Feature / Property | Natural Wood | ALumverde |

| Sustainability | Requires logging, impacts forests, limited lifespan | Wood-free, aluminum-based, replicates nature’s beauty without depleting natural wood |

| Durability & Weather Resistance | Prone to rot, warp, splinter, insect damage, fades, requires sealing | Superior – Excellent color fastness; coating layer prevents cracking and remains stable under outdoor heat. UV Resistance, Waterproof, Fireproof, Anti-deformation/Low expansion. Excellent UV protection. Durability against weathering. |

| Maintenance | High: Requires regular sanding, staining, sealing, painting | Low: No painting, staining, or sealing required. Scratches can be repaired with special finishing treatment. |

| Stability | Susceptible to expansion, contraction, bending, cracking due to moisture and temperature changes | Excellent: Low expansion to achieve seamless design without concern of bending & cracking. High stability and longer durability. |

| Fire Resistance | Combustible, high fire risk | Excellent (highest rating), Class A fire resistance, non-combustible |

| Heat Insulation | Natural insulator, but can absorb and retain heat | Superior: ALumverde > Alu-WPC Product > Alu Product. Special blending and molding technologies make it 30% cooler than other aluminum products in outdoor use. |

| Weight | Varies, but typically heavy compared to alternatives | Light. Half weight than WPC cladding. |

Against WPC (Wood-Plastic Composite): Elevating Performance and Aesthetics

While WPC aimed to combine wood aesthetics with plastic durability, it often falls short in critical areas, particularly when compared to ALumverde’s advanced technology. Traditional WPC, with its slightly rough texture, offered a wood-like tactile experience, but it faced limitations in UV resistance and waterproofing, especially in harsh environments. The evolution of WPC into its second generation (Capped WPC) brought a breakthrough with a protective technology, which inspired ALumverde.

| Feature / Property | Alu-WPC Product | ALumverde |

| Technique | Classic WPC Coated | Surlyn Resin Coated |

| Appearance | Wood-like | Wood-like |

| Touch | Natural wood texture (cannot be made in 3D relief) | Smooth or natural wood texture (depending on post-processing); 3D relief possible. Authentic Texture, 3D Touching, Elegant Wood feeling. |

| Texture | Monotonous texture | Multiple textures: Woodweave, Wood Grain, Matte Brush. Can be sanded or plain. |

| Color | Monotonous color | Multiple colors: Teak, Antique, Walnut, Ashwood, IPE, Dark Grey. Bi-color options (2 colors in 1 piece). |

| Heat Insulation | ALumverde > Alu-WPC Product > Alu Product | ALumverde > Alu-WPC Product > Alu Product. Reduces heat absorption by up to 30% with Mexytech special technique. |

| Weather Resistance | Good – Good color fastness; coating layer at risk of cracking under outdoor heat | Superior – Excellent color fastness; coating layer prevents cracking and remains stable under outdoor heat. Uses Surlyn, the same material as golf surface, for better protection against color fade and rust. |

| Scratch Resistance | Common – Cannot be repaired | Good with special finishing treatment; scratches can be repaired. |

| Applicability & Stability for High-Rise Building | Limitations in UV resistance and waterproofing in harsh environments | Can achieve length up to 6 meters with no concern of bending and cracking. Its super low water absorption and expansion makes it the most stable material for high-rise building. |

Against Traditional Powder-Coated Aluminum: A Revolution in Touch and Longevity

While powder-coated aluminum offered an improvement over raw metal, it still fell short in delivering the authentic tactile experience and long-term aesthetic stability that architects and designers desire. ALumverde addresses these aesthetic and longevity shortcomings head-on.

| Feature / Property | Alu Product (Powder Coated) | ALumverde |

| Technique | Powder Coated | Surlyn Resin Coated |

| Touch | Strong metallic feel; texture is relatively poor | Smooth or natural wood texture (depending on post-processing); 3D relief possible. Say goodbye to the cold of metal, and embrace the warmth experience. Distinctive life-like texture, replicates natural texture and appearance of real wood. |

| Weather Resistance | Common – Significant variation depending on coating quality; poor-quality powder may cause fading and peeling | Superior – Excellent color fastness; coating layer prevents cracking and remains stable under outdoor heat. Ultra UV Protection & Waterproof. Long-lasting color fastness vital for outdoor use. |

| Scratch Resistance | Common – Cannot be repaired | Good with special finishing treatment; scratches can be repaired. |

| Appearance | Wood-like | Authentic WPC appearance & Feeling, 3D-touching and beautiful wood feeling. Creates a lifelike wood texture and unlocks a broader spectrum of colors and surface finishes. |

| Color Options | Various colors | Multiple colors: Teak, Antique, Walnut, Ashwood, IPE, Dark Grey. Bi-color options (2 colors in 1 piece). |

| Texture Options | Various textures | Multiple textures: Woodweave, Wood Grain, Matte Brush. Can be sanded or plain. |

ALumverde: The Definitive Choice for High-Rise Buildings

The unique combination of advanced technology and superior material properties makes ALumverde an ideal solution for modern architecture, particularly in the demanding environment of high-rise buildings, commercial spaces, and public premises.

Unparalleled Fire Safety for Vertical Structures

Fire safety is paramount in high-rise constructions. ALumverde products are non-combustible aluminum materials. They boast a Class A fire resistance rating, which is the highest standard in fire resistance. This excellent fireproof rate, meeting the aluminum standard of fire resistance, is essential for high-rise buildings and commercial spaces, providing a natural shield and suppressing fire spread.

Superior Structural Stability and Durability Under Demanding Conditions

ALumverde’s advanced design and material composition ensure exceptional structural stability and durability:

- Low Expansion and Seamless Design: The products feature low expansion rates, enabling seamless design without concerns of bending or cracking.

- Load-Bearing Capacity: Made with 6063-T5 Aluminum, ALumverde offers excellent load-bearing capacity and standardized strength, ensuring durability for over 25 years.

- Length and Stability: ALumverde can achieve lengths of up to 6 meters per piece without concerns of bending and cracking. This super low water absorption and expansion rate makes it the most stable material for high-rise building applications.

Streamlined Installation and Long-term Maintainability

Ease of installation and long-term maintainability contribute significantly to project efficiency and cost-effectiveness.

- Easy Installation: ALumverde’s light weight (e.g., LuxeFlow Decking at 1.04 lbs/ft or 1.55kg/m, Bi-color Decking at 0.96 lbs/ft or 1.43 kg/m, AC-ST01 Tube at 0.16lbs/ft or 0.24kg/m, AC-WP18 Cladding at 1.13lbs/ft or 1.69kg/m, AC-WP19 Cladding at 1lbs/ft or 1.49kg/m) saves 1/3 time and labor compared to alternatives. With half the weight of WPC cladding, it can be installed on double wider spans.

- Lower Auxiliary Cost: The streamlined installation process contributes to lower auxiliary costs.

- Various Installation Methods: ALumverde offers various installation methods depending on the product series:

- Decking: Typically uses aluminum joists (AL02, MJ-AL) for under structure.

- Tubes: Can be installed using innovative clip-hidden methods, threaded rivets, refined AB hole installation, U-clip installation, or interior U clip installation. Accessories like L Joist, L Bracket, and Tube Cap are available.

- Cladding: Involves installing aluminum joists with a 1m span, drilling siding trims, screwing panels on the edge, and fixing side trims. Accessories include aluminum joists (AL02, MJ-AL), aluminum end trims (AF01, AC04), aluminum corner trims (AC01), and aluminum transition trims (AC02).

- Maintainability: Scratches can be repaired with special finishing treatment, unlike many traditional materials.

Design Versatility and Aesthetic Impact

ALumverde empowers designers and architects with boundless creative freedom, offering a wide array of options to realize diverse aesthetic visions.

Extensive Product Range and Customization Options

ALumverde offers a complete range of products to meet every project’s needs:

- Decking: Includes LuxeFlow Decking (AD01, 171.2×22.4mm) with in-built drainage channels and Bi-color Decking (AD03, 138x23mm) offering two stunning colors in one panel.

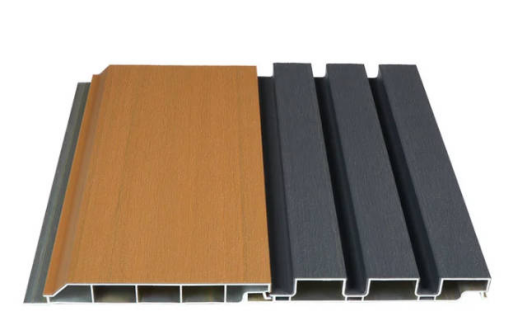

- Cladding: Features Slat Cladding (AC-WP18, 167.5x24mm) creating rhythmic vertical patterns and Shiplap Cladding (AC-WP19, 167x21mm) for a modern, elegant soffit or wall application.

- Tubes: As ALumverde’s most variable profiles, they come in square, round, and rhombus shapes in over twenty sizes. Available models include AC-ST01 (15x25mm), AC-ST02 (30x50mm), AC-ST03 (50x60mm), AC-ST04 (40x80mm), AC-ST05 (30x120mm), and AC-ST06 (50x100mm). They can be used for pergolas, railings, and screening systems.

- Accessories: A full suite of accessories is available for seamless installation and consistent beauty across all product lines, including joists, brackets, caps, gutters, and various trims.

- Customization: ALumverde supports more customized profiles and textures with FCL (Full Container Load) MOQ (Minimum Order Quantity), and customized colors with negotiable MOQ. Irregular cutting and punching/drilling are also possible.

Rich Textures, Colors, and Dual-Tone Designs

ALumverde excels in replicating the natural beauty of wood while offering extensive aesthetic choices:

- Authentic Wood Feeling: Unlike traditional powder-coated aluminum, ALumverde features a variety of authentic wood-grain finishes that replicate the natural texture and appearance of real wood. The Surlyn resin co-extrusion creates a lifelike wood texture. Its 3D touching provides an elegant wood feeling.

- Available Colors: Products come in a selection of popular and versatile colors: Teak, Antique, Walnut, Ashwood, IPE, and Dark Grey.

- Texture & Finish Options: Choices include Woodweave, Wood Grain, and Matte Brush. Some products also offer Sanded or Plain finishes.

- Bi-Color Option: The bi-color decking offers two stunning colors in one panel, allowing for flip, mix, and transformation of spaces, where one side provides the warmth of natural wood and the other a sleek, modern finish.

Beyond Aesthetics: Functional Design Elements

ALumverde integrates functional benefits that enhance comfort and performance in various environments:

- Heat Insulation: Engineered for all seasons, ALumverde’s advanced cladding technology seamlessly moderates temperature fluctuations, delivering year-round comfort. Its special blending and molding technologies result in up to 30% less heat absorption in outdoor use compared to other aluminum products, ensuring a more comfortable walking experience even under the burning sun.

- UV Protection and Color Fastness: The Surlyn resin layer provides excellent UV protection and long-lasting color fastness, which is vital for outdoor use and prevents color fade and rust.

- Water Management System: LuxeFlow decking features an innovative design that combines seamless water gathering and drainage. The decking edge acts as a channel to gather water from the surface, which then flows through the channel. Designers can utilize matching gutters (ADF01, MC06) to guide water to drainage points, ensuring proper water management from the surface to the lower structure.

- Ultra Slip Resistance: ALumverde products adhere to fundamental safety principles, offering ultra slip resistance for decking applications.

Conclusion

ALumverde represents a significant leap forward in building materials, seamlessly blending the robust strength of aluminum with the authentic beauty and texture of natural wood. Through its innovative Surlyn resin co-extrusion technology, stringent production processes, and commitment to superior performance, ALumverde provides an unparalleled alternative to traditional wood, WPC, and powder-coated aluminum.

From its Class A fire resistance and exceptional structural stability to its design versatility and ease of installation, ALumverde is engineered to meet the highest standards of safety, durability, and aesthetics required for modern high-rise buildings, commercial spaces, and public premises. It offers not just a material, but a complete system of crafted smart design, empowering architects and designers to create spaces that inspire, endure, and elevate, all while honoring a vision of nature care without depleting natural resources.

Choosing ALumverde means opting for a future where architectural beauty coexists harmoniously with safety and sustainability. It’s more than just building; it’s about crafting legacies that reflect both innovation and respect for the environment.